Despite the importance of proper refrigeration system operation in commercial refrigeration repair Los Angeles, owners often encounter a problem: the refrigerator compartment won’t freeze.

This malfunction can lead to food spoilage and significant losses, so prompt identification and troubleshooting are crucial.

The main reasons why a refrigerator compartment stops freezing can be varied and include both technical failures and improper use of the equipment. Cold production is disrupted due to low freon levels, compressor contamination, or leaks in the system. Thermostat malfunctions or faulty temperature sensors can also be the cause.

To ensure reliable operation of refrigeration units and avoid serious breakdowns, it is recommended to contact professionals specializing in commercial refrigeration repair Los Angeles. Proper diagnosis and timely troubleshooting help extend the life of refrigeration systems and maintain the required temperature conditions in the compartments.

Why Does the Refrigerator Chamber Remain Warm? A Practical Guide to Diagnostics and Repair

If your refrigerator chamber isn’t freezing and remains warm, there may be several possible causes. It’s important to correctly identify the source of the problem to effectively troubleshoot and restore the unit’s functionality. This article discusses the main causes and provides recommendations for diagnosing and repairing them, which will help reduce the time and cost of troubleshooting.

Before repairs, we recommend performing a basic check of external factors, such as the power supply and proper installation of the refrigerator, as well as ensuring there are no visible damage or blockages in the cooling system.

Main Causes and Their Diagnostics

- Insufficient freon is one of the most common causes of a refrigerator chamber’s warm state. Due to a leak or improper charging, the refrigeration system does not create the necessary pressure for cooling. Checking the freon level is done using specialized equipment or by calling a specialist.

- Compressor malfunction – if the compressor is not working or is not working properly, the system is unable to provide cooling. Check its startup, motor resistance, and excessive noise.

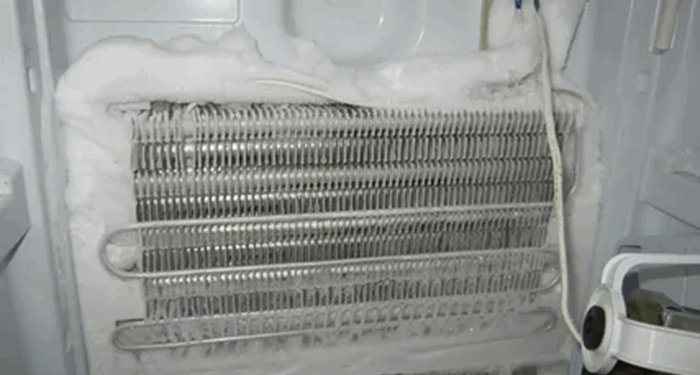

- Clogged capillary tube or filter-drier – ice or dirt buildup prevents the refrigerant from flowing properly. Diagnostics include a visual inspection and checking the system’s condition.

Practical Troubleshooting Guide

- Checking and Refilling Freon: If a deficiency is detected, top up the system with the specified amount, following the manufacturer’s recommendations.

- Repairing or Replacing the Compressor: If the compressor is faulty, it must be replaced or repaired in a specialized workshop.

- Cleaning the System: Remove blockages by cleaning the capillary tube and replacing the filter drier to ensure free flow of refrigerant.

Additional Tips

| Problem | Possible Cause | Recommended Solution |

|---|---|---|

| Absence Cold | Lack of freon | Refill the system |

| Compressor does not turn on | Damaged electromagnetic relay or starting capacitor | Checking and replacing parts |

| Frost formation on the rear wall | High humidity or faulty temperature sensor | Fixing leaks and replacing the sensor |

Compressor Problems: How to Identify and Troubleshoot

To identify problems with the compressor, it is necessary to perform a series of diagnostic steps, carefully listen to its operation and pay attention to the nature of the sounds, as well as the presence of unusual vibrations or odors. In some cases, certain symptoms can quickly identify the cause of the malfunction.

Common Causes of Compressor Malfunction and How to Fix Them

- The compressor won’t turn on: This could be due to the power supply, thermostat, or compressor itself. Check for voltage, solenoid contacts, and circuit. If these components are faulty, they will need to be replaced or repaired.

- The compressor shuts off quickly or burns out: This could be due to overheating, contaminated or insufficient oil, or a faulty electrical circuit. Clean and check the oil, and top it up if necessary.

- Decreased compressor performance: This is most often due to worn valves, clogging, or mechanical damage. In this case, an inspection and possibly replacement of damaged parts will be required.

How to check the compressor’s operation

- Check whether the compressor can be heard when turned on.